Harness the Strategic Side of Concrete Scanning for Unparalleled Task Success and Quality Control

In the world of modern-day building and construction and framework advancement, the use of concrete scanning innovation has emerged as a critical tool for ensuring task success and keeping top quality requirements. This ingenious method offers a strategic side by supplying crucial understandings right into the architectural stability of concrete elements, therefore making it possible for notified decision-making throughout the project lifecycle. By diving right into the depths of concrete compositions and revealing concealed anomalies, stakeholders can proactively address possible dangers, streamline procedures, and enhance resource appropriation. The true power of concrete scanning exists not only in its capacity to improve task results but also in its capacity to revolutionize traditional techniques, setting a new standard for precision and efficiency in the building and construction industry.

The Importance of Concrete Scanning

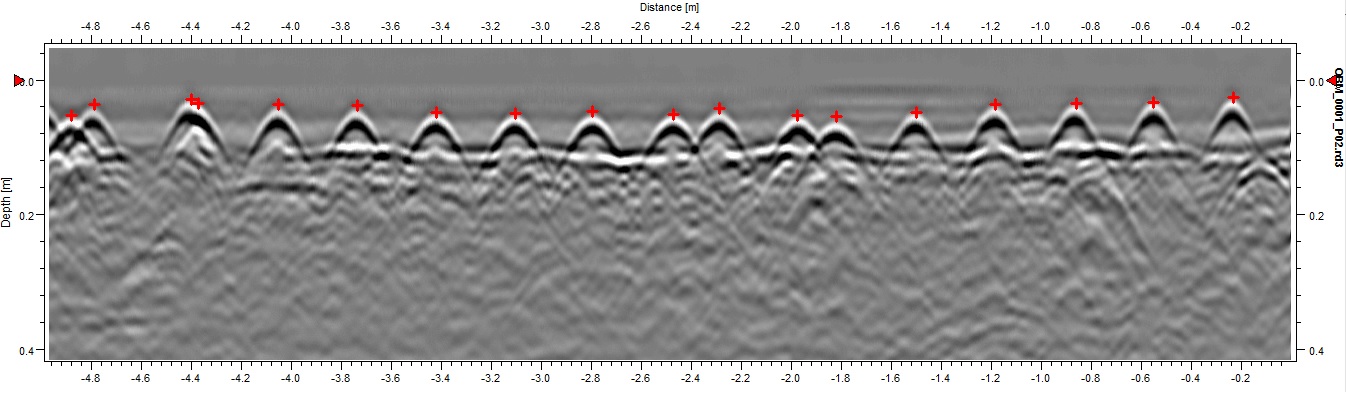

Concrete scanning is a crucial step in building and construction projects to guarantee the safety and honesty of frameworks. By using numerous scanning technologies such as Ground Passing Through Radar (GPR) and electromagnetic induction, building and construction groups can non-destructively assess the subsurface of concrete frameworks to identify prospective threats like rebar, conduits, or post-tension cords. This details is important for task managers, engineers, and specialists to make informed decisions and prevent expensive blunders throughout the construction process.

One of the main factors why concrete scanning is so crucial is its capacity to prevent accidents and injuries on the building website. Mistakenly puncturing a real-time electric avenue or destructive post-tension wires can have catastrophic consequences, not only in regards to safety and security but also in terms of job delays and economic effects. By performing complete concrete scanning before any boring, cutting, or coring activities, building teams can minimize dangers and produce a safer working atmosphere for everybody included.

In addition to security considerations, concrete scanning additionally plays a crucial role in ensuring the lasting toughness and high quality of the framework. By discovering any kind of problems or anomalies concealed under the surface, such as gaps or delamination, early treatment can be executed to address these problems before they intensify into even more substantial troubles. Ultimately, investing in concrete scanning is a proactive step that can conserve time, cash, and resources over time, while likewise promoting the greatest criteria of building quality.

Advanced Technology for Exact Results

In addition, 3D scanning technologies offer an extensive view of the subsurface atmosphere by developing thorough electronic versions. These designs supply useful insights into the structural integrity of concrete elements and aid in recognizing possible weak points before they escalate right into significant concerns. By integrating these sophisticated technologies into concrete scanning techniques, construction groups can streamline operations, decrease project hold-ups, and make sure the general top quality and success of the job. The precision and performance used by these tools contribute dramatically to the job's success by helping with informed decision-making and developing quality guarantee procedures.

Enhancing Project Performance and Timelines

Moreover, concrete scanning enables teams to identify potential risks and structural weak points early on, allowing for punctual removal and protecting against mishaps that could derail task timelines. The real-time data given by scanning devices assists in educated decision-making, bring he said about smoother sychronisation among various trades and stakeholders. This boosted partnership reduces conflicts, improves performance, and eventually accelerates job shipment.

Additionally, by proactively addressing concerns via concrete scanning, building teams can abide by routines more properly, lower downtime, and enhance resource appropriation. The ability to identify concealed barriers and confirm structural stability efficiently adds to overall project effectiveness and timelines, ensuring effective end results and client contentment.

Ensuring Security and Threat Mitigation

Danger mitigation strategies can be enhanced via the in-depth information supplied by concrete scanning, enabling task teams to make enlightened decisions that minimize the likelihood of unanticipated events. In addition, by accurately drawing up subsurface problems, professionals can stay clear of expensive rework, hold-ups, and damage to existing frameworks, better contributing to general task safety and success. Implementing concrete scanning as a regular method not only makes sure a more secure work atmosphere yet also imparts self-confidence in stakeholders concerning the job's dedication to quality and danger monitoring.

Quality Control With Concrete Scanning

Concrete scanning plays a critical duty in upholding quality control standards within building and construction projects. By utilizing sophisticated scanning technologies such as Ground Permeating Radar (GPR) and Concrete X-ray, task supervisors and designers can ensure the integrity and quality of concrete structures. With concrete scanning, prospective flaws, such as gaps, splits, or reinforcing bar congestion, can be detected non-destructively, enabling timely interventions to keep the structural honesty of the project.

Quality control with concrete scanning not only assists in determining existing problems however additionally makes it possible for proactive steps to avoid future problems that could compromise the safety and security and longevity of the structure. By performing thorough scans at crucial phases of construction, teams can verify the precision of architectural plans, confirm the placement of important components, and address any kind of inconsistencies without delay. This aggressive strategy minimizes rework, reduces pricey hold-ups, and eventually results in the distribution of high-grade, sturdy structures that surpass or satisfy market requirements.

Final Thought

In conclusion, concrete scanning plays an important duty in ensuring job success, top quality, efficiency, and safety assurance. The calculated side supplied by concrete scanning allows for proactive risk mitigation and boosts total task monitoring.

In the realm of modern building and facilities advancement, the use of concrete scanning modern technology has actually arised as a pivotal tool for ensuring project success and maintaining high quality requirements. By integrating these sophisticated innovations into concrete scanning techniques, construction groups can streamline workflows, reduce project delays, and ensure the overall quality and success of the task.Provided the vital nature of job effectiveness and timelines article in building management, the focus currently changes towards guaranteeing safety and mitigating threats within the project environment.Concrete scanning plays a pivotal duty in maintaining high quality assurance standards within building and construction jobs. By utilizing innovative scanning innovations such as Ground Penetrating Radar (GPR) and Concrete X-ray, task managers and designers can make sure the integrity and top quality of concrete frameworks.

Comments on “Grasping RainierGPR Concrete Scanning: Necessary Advice”